Characteristics, classification and Comparison of Gate Valves

The

gate valve has a gate as the opening and closing component. A valve that is driven by the valve stem to move the gate up and down is called a gate valve.

Characteristics of gate valves

1) Advantages of gate valves

Low fluid flow resistance

Low torque required for opening and closing

The flow direction of the medium is not restricted.

Water hammer phenomenon during opening and closing

The body structure is relatively simple and the manufacturing process is good.

2) Disadvantages of gate valves

The overall size and installation height are relatively large. The required installation space is also large. During the opening and closing process, there is relative friction and wear on the sealing surface, which can even cause scratches at high temperatures.

Gate valves generally have two sealing surfaces, which add some difficulties to processing, grinding, and maintenance. Gate valves have a wide range of applications. They are usually used for water supply pipelines with a nominal diameter greater than or equal to DN50.

The classification of gate valves

Gate valves can be divided into threaded gate valves, flange gate valves, and welded gate valves according to their connection methods. They can be divided into parallel gate plates and wedge gate plates according to their structural characteristics. According to the valve stem structure, there are rising stem (lifting rod) gate valves and non-rising stem (rotating rod) gate valves.

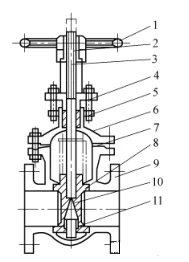

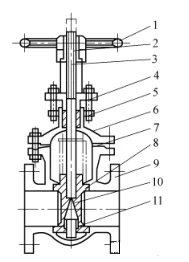

1) Rising stem parallel double gate valves

The rising stem parallel double gate valve is shown in the Figure 1. Its gate consists of two symmetrical and parallel disks. When the gate descends, the top wedge placed at the bottom of the gate expands the two gates outward and presses them tightly against the valve seat, making the valve tightly closed. When the gate rises, the wedge detaches from the disc. When the disc reaches a certain height, the wedge is lifted by the protrusion on the disc and rises with the gate.

This valve has a simple structure, and the processing, grinding, and maintenance of the sealing surface are simpler than wedge gate valves. However, its sealing performance is poor, and it is suitable for media with a pressure not exceeding 1.0MPa and the temperature not exceeding 200 degrees.

Figure 1: Rising stem parallel double gate valves

1- Handwheel 2- Valve stem nut 3- Valve stem 4- Packing gland 5- Packing 6- Valve cover

7- Gasket 8- Sealing ring 9- Valve body 10- Gate 11- Top wedge

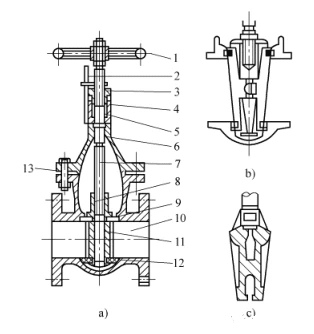

2) Non-rising stem wedge gate valve:

Figure 2 shows a non-rising stem wedge gate valve, whose sealing surface is inclined. It forms an angle. The higher the medium temperature, the greater the angle. The wedge gate is divided into single gate, double gate, and elastic gate, as shown in Figures 2a, b, and c. The processing, grinding, and maintenance of wedge gate plates are more complicated than that of parallel gate plates, but their sealing performance is better.

Figure 2 Non rising wedge gate valves

a) Wedge single gate b) Wedge double gate c) Wedge elastic gate

1- Handwheel 2- Indicator 3- Gland 4- Packing box 5- Packing 6- Valve cover

7- Valve stem 8- Valve stem nut 9/12- Sealing ring 10- Valve body 11- Gate 13- Gasket

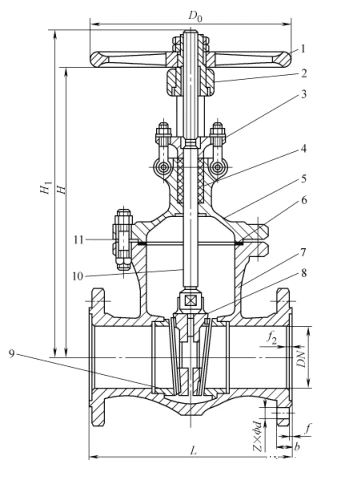

3) Elastic gate valve

The elastic gate valve, as shown in Figure 3, has the advantages of simple structure and reliable use, as well as the ability to generate small elastic deformation, increasing the tightness of closure.

Figure 3 Elastic Gate Valve

1- Handwheel 2- Valve stem nut 3- Packing gland 4- Packing 5- Valve cover 6- Gasket

7- Valve body 8- Gate 9- Sealing ring 10- Valve stem 11- Connecting bolt

Comparison of gate valves

In a rising stem gate valve, the thread of the valve stem is matched with a sleeve nut with a hand-wheel. The lower end of the valve stem has a square head embedded in the gate plate. When the hand-wheel is rotated, the valve stem and gate plate move up and down. When it is open, the valve stem extends out of the hand-wheel, which has the advantage of being able to determine the degree of valve opening from the extended length of the valve stem, and the valve stem does not directly come into contact with the conveying medium.

The disadvantage is that the valve opening height is large, and there must be sufficient space for the valve stem to extend outside the installation site. When installing on site, it is important to pay attention to this point. The external thread of the stem of a non-rising stem gate valve is matched with the internal thread embedded in the valve. Therefore, when we rotate the hand-wheel, the stem rotates, causing the gate inside the valve to move up and down. However, the stem cannot move up or down. The installation of non-rising stem gate valves takes up little space, and the conveying medium is in direct contact with the valve stem. The degree of valve opening cannot be determined by the valve stem. Whether it is a rising stem gate valve or a non-rising stem gate valve, the installation of gate valves needs to be horizontal. The valve stem should be vertically upwards and should not tilt. It is strictly prohibited to install the valve stem downward.