What is the difference between a globe valve and a gate valve?

Posted: 07/26/2019 16:54:48 Hits: 485

Can we use a globe valve instead of a gate valve, or vice versa?

Let us introduce the difference between the globe valve and the gate valve.

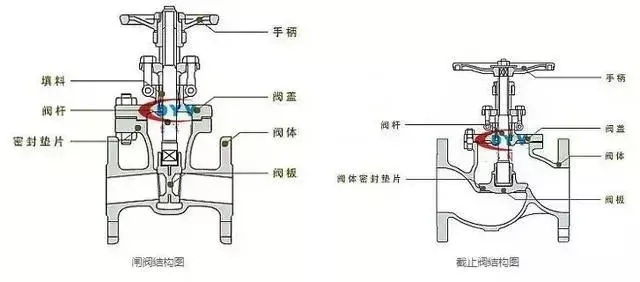

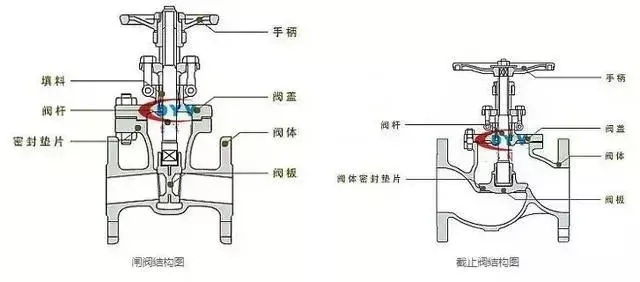

01. Structurally

When the installation space is limited, you should pay attention to the selection:

The gate valve can be tightly closed with the sealing surface by the medium pressure and tightly closed to achieve a non-leakage effect. During valve opening and closing, the sealing surface of the valve plug and the valve seat always contact and rub against each other, so the sealing surface is easy to wear, and when the gate valve is close to close, the pressure difference between the front and the rear of the pipeline is large, and the sealing surface wear is more serious.

The structure of the gate valve is more complicated than that of the shut-off valve. From the aspect of the shape, the gate valve is higher than the shut-off valve in the same diameter, and the shut-off valve is longer than the gate valve. In addition, the gate valve has a rising stem or non-rising stem, which the shutoff valve does not have.

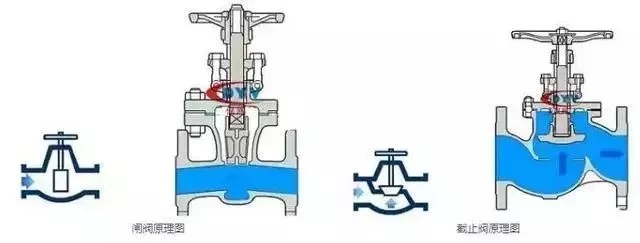

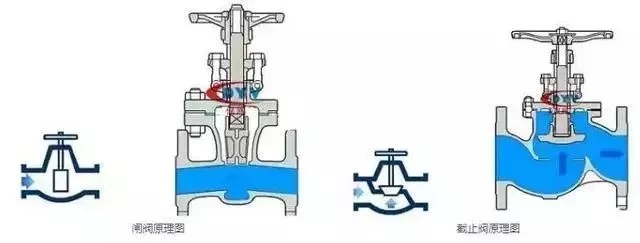

02. Working principle

When a globe valve is opened and closed, it is a rising stem type. That is to say, turning the hand wheel, the hand wheel will rotate and lift together with the valve stem. Whereas, for gate valves, hand wheel is rotated in order that the valve stem can rise and fall, and the position of the hand wheel itself is unchanged.

Flow rates vary, gate valves are required to be fully open or fully closed, while globe valves are not required. For globe valves, there are specified inlet and outlet directions, and the gate valve has no requirements for inlet and outlet.

In addition, the gate valve has only two states of full opening or full closing, the stroke of the shutter opening and closing is large, and the opening and closing time is long. The valve plate movement stroke of the shut-off valve is much smaller, and the valve plate of the shut-off valve can be stopped at a certain position during the movement for flow regulation. The gate valve can only be used for cutting off and has no other functions.

03. Performance difference

The globe valve can be used for both cut-off and flow regulation. The fluid resistance of the shut-off valve is relatively large, and it is laborious to open and close. However, since the distance between the valve plate and the sealing surface is short, the opening and closing stroke is short.

Because the gate valve can only be fully open and fully closed, when it is fully open, the medium flow resistance in the valve body passage is almost zero, so the opening and closing of the gate valve will be very labor-saving, but the gate is far away from the sealing surface, and the opening and closing time is long.

04. Installation and flow direction

The effect of the gate valve flowing in both directions is the same. There is no requirement for the direction of the inlet and outlet, and the medium can flow in both directions. The globe valve needs to be installed in strict accordance with the direction marked by the arrow of the valve body. There is also a clear provision for the direction of the inlet and outlet of the shut-off valve. The flow direction of the shut-off valve specified by the "three-way" of the valve in China is always from top to bottom.

In globe valve applications, the pipeline is clearly not on a horizontal line viewed from the outside. The gate valve flow path is on a horizontal line. The stroke of the gate valve is larger than that of the shut-off valve.

From the point of view of the flow resistance, the flow resistance of the gate valve is small at full opening, while the flow resistance of the globe valve is large. The flow resistance coefficient of the ordinary gate valve is about 0.08~0.12, the opening and closing force is small, and the medium can flow in two directions. The flow resistance of a common shut-off valve is 3-5 times that of a gate valve. When opening and closing, it is necessary to close by force to achieve good sealing performance. The spool of the shut-off valve only contacts the sealing surface when it is completely closed, so the wear of the sealing surface is small. For globe valves needing a actuator equipped because of the large flow resistance, we should pay attention to the adjustment of the torque control mechanism.

There are two ways to install the globe valve. One is that the medium can enter from the bottom of the valve core. The advantage is that the packing is not under pressure when the valve is closed, the life of the packing can be extended.

Moreover, the work of replacing the packing can be carried out under the condition that the pipe in front of the valve is under pressure; the disadvantage is that the driving torque of the valve is large, about 1 times of the upward flow, the axial force of the valve stem is large, and the valve stem is easy to bend.

Therefore, this method is generally only applicable to small-diameter globe valves (below DN50), and the shut-off valves above DN200 use the medium to flow in from above. (For an electric shut-off valve, the medium generally flows in from above) The disadvantage of the medium entering the way from the top is exactly the opposite of the way of entering below.

05. Seal

The sealing surface of the globe valve is a small trapezoidal side of the valve core (specifically, the shape of the valve core). Once the valve core is detached, it is equivalent to the valve closing (if the pressure difference is large, of course, the sealing performance is not good, but the anti-reverse effect is not bad). The gate valve is sealed by the side of the valve core, and the sealing effect is not as good as that of the shut-off valve. For a gate valve, the valve core falling off is not equivalent to the valve closing like a shut-off valve.