Connecting lever

butterfly valve is a form of butterfly valve’s structure, which is mainly used in smelting blast furnace hot blast stove system and preheating furnace system. And it is applied in flue valve, gas cut-off valve, burning gas valve, combustion air shut-off valve, cold blast valve, etc. It plays the role of cutting off in the system.

1. Structure

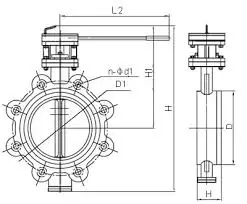

Connecting lever butterfly valve is mainly composed of actuating device, valve body, principal shaft, lever, valve disc, shaft end seal, shaft end supports and other components.

2. Working principle

The main technology of connecting lever of butterfly valve focuses on the middle part of the butterfly valve’s lever. The connecting lever can be respectively classified into active lever, fixed lever and auxiliary lever. According to the connecting lever butterfly valve’s lever structure, it is known that one end of active lever is connected with spindle through end key or pin, and the other end of active lever is connected with the fixed bar on the valve disc through the main shaft and the valve body. Then, the active lever plays a role of fixing and support in the entire process of movement. One end of the auxiliary lever is connected with the fixed lever, and the other end is connected with the valve disc. Then, the auxiliary lever plays a role of realizing trajectory in the process of movement. Connecting lever part of butterfly valve can be thought of as a four-lever linkage. It can realize a vertical upward movement the moment when this valve disc was opened, making the sealing face of valve disc and valve body quickly separate. Then, there are no relative frictions for the two sealing faces, making sure the service life of the butterfly valve.

The life of butterfly valve is associated with three main factors as follows: the quality of butterfly valve itself, the valve working conditions and the installation and maintenance. Quality of butterfly valve itself is related to raw material, structure and the process. The selection of engineering ceramic materials can effectively improve the wear resistance and corrosion resistance of butterfly valve. It is acceptable to be handled by heat treatment and surface hardening treatment. We have no choice of the operation condition of butterfly valve. What can be accepted is that it is a must to choose suitable working conditions. In addition, correct installation methods of butterfly valve and the correct operation and maintenance of butterfly valve also can improve the service life of butterfly valve.